Some Known Details About Plastic Extrusion Companies

Wiki Article

How Custom Plastic Extrusion Manufacturers can Save You Time, Stress, and Money.

Table of ContentsCustom Plastic Profiles for DummiesPlastic Extrusion Companies Fundamentals ExplainedA Biased View of Plastic Extrusion CompaniesAll about Plastic Extrusion CompaniesOur Plastic Extrusion Profiles Statements

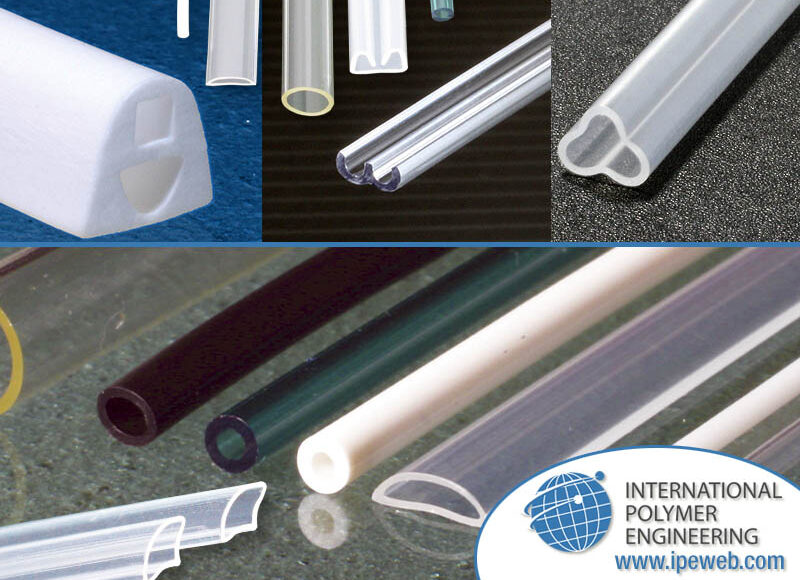

We can also offer personalized laminations and also would more than happy to send you samples upon demand. We presently have seven lamination stations that can take care of various sorts of personalized plastic extrusions. We provide customized product packaging as well as are currently packaging an extruded profile product that is offered to a "Huge Box" Business.This process is understood as extrusion. Extrusion is utilized to develop objects of a taken care of cross-sectional account, such as pipelines, tubes, as well as poles. The raw product, known as the "extrudate", is very first softened by home heating.

Extrusion can be made use of to develop items from a range of products, consisting of metals, plastics, and compounds. It is made use of in a range of markets, including auto, construction, and also production.

7 Simple Techniques For Extrusion Of Plastics

There are several firms that handle this kind of manufacturing. These companies can help you to design the ideal item for your needs and afterwards create it making use of the extrusion process. If you have a need for personalized products, personalized extrusion relevant handling may be the best remedy. Prototyping your next essential task can be as simple as calling Alpha Customized Extrusions, Inc.Additionally, Alpha Custom Extrusions, Inc. provides a host of secondary capabilities to complete your total project. Call today!.

Include joints, seals, leading coats, multiple colors and other features

Plastic Extruded Profiles - Truths

Lead times vary based upon our Finite Ahead scheduling system. Our invoice of your purchase order begins the scheduling procedure. Is all tooling created internal? Yes, all tooling is designed and also produced by Sandee. What is the standard lead time for a manufacturing order? The characteristics of personalized manufacturing typically cause fast modifications to tooling, manufacturing and manufacture schedules.

We can generate an extra exact quote if we can reference a Pantone shade number. If no Pantone number is readily available, anything can be customized color matched. How long does a custom color suit take? It typically takes 10 working days to get a color chip to you for approval, and 10 additional functioning days to generate the custom-made shade concentrate from the accepted color chip.

They are provided in order of preference. DWG Automobile, CAD 2000 DWG Any alteration of Automobile, CAD DXF Auto, CAD 2000 DXF Any type of alteration of Car, CAD Please get in touch with if you can not submit the file in one of these formats (https://businesslistingplus.com/profile/k3ll3rpl4st8/). What is the maximum possible size of a profile? The extrudable account is determined by determining its established size.

How Plastic Extrusion Companies can Save You Time, Stress, and Money.

We've been doing it right considering that 1962 and are positive that your project will gain from our comprehensive experience in:. extrusion of plastics. https://docs.google.com/document/d/1KAfkPzO5-Yu_PALOASH35AVBEQG7f7VOeFyFmklQ5qw/edit.NCS additionally supplies co-extruded products of various durometers and also different materials that are co-extruded into the same component. If you have concerns about co-extrusions or any of our extruded plastic products, please reach out to our team to learn much more - extrusion of plastics.

Extruded plastic shapes are created using a high-volume production process where raw plastic resin material is melted, then required via a die to form a constant account. To produce plastic extruded forms, the material is put right into the barrel of an extruder after that gradually melted. Heat and stress is after that used to require the molten plastic right into a die.

More About Extruded Plastic Profiles

With just a small alteration, extrusion molding can go from producing complicated forms to plastic sheets. After plastic leaves the extruder, it stays hot and can be more adjusted. This allows producers to alter the shape of extruded plastic using rollers, footwear, or dies to fulfill the specific needs of lots of applications.Extruded plastics are used throughout commercial and also industrial applications, with several of the most usual being tubes, poles, and also specialized profiles. Applications for extruded plastic tubing, poles, and also specialized profiles consist of:.

Ask us to fix your problems and depend on us for accuracy as well as on-time delivery.

At Astro Plastics, our tenure in the sector and selection of top-end capabilities enable us to supply on even one of the most complex customer demand. Our group of experts functions very closely with you to tackle your custom-made plastic extrusion needs from principle to conclusion, ensuring you get the ideal item at the correct time.

Report this wiki page